Introduction:

Nano ceramic e-coating (hereinafter referred to as e-coating) is a cutting-edge technology that involves the application of a thin ceramic layer onto the surface of jewellery (or any conductive metal object, could be door handle as well). The main reasons to use this technology is to enchance the overall aesthetics of the jewellery by a sleek, colorful finish and to protect the metal.

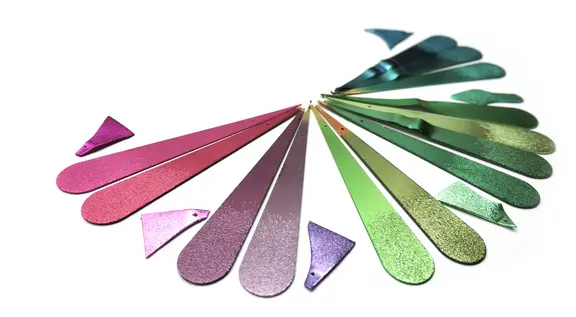

E-coating is very durable. The nano-sized ceramic particles adhere tightly to the jewellery surface, forming a protective shield that guards against scratches, tarnishing, moisture, chemicals, and fading. The coating is also hypoallergenic which is especially handy when it is applied on top of base metals like brass, copper etc. The e-coating can be applied in various colors and finishes, the final color depends on the color of the underlying metal. As the coating is applied by electrolysis (more precisely by cataphoresis), the object to be coated must be from conductive metal. The process involves preparing and cleaning the object, immersing it into the bath filled with special dye solution and applying electricity. As a result, the thin ceramic layer is deposited on top of the object. This needs curing in the oven as a final step.

In the workshop you will

As a result the student who has completed the course:

ISA supplies:

You supply:

Since we will be working with chemicals, participants are required to bring for their personal safety and comfort during the course:

Materials and tools:

Optional:

You may take with you different metal pieces / wire / chains etc and unfinished or readymade jewellery pieces, so you could practice with more real-life situations. Those pieces have to be clean (without any residue or traces of polishing compound). The test objects should have a maximum size of 8 x 8 x 8 cm.

The International Jewellery Academy was initiated by Tabea Reulecke as part of her masterthesis in 2015 and is organised by Carolin Denter, Oranna Kammann and Theo Smeets.

Carolin Denter (Management)

Oranna Kammann (Registration)

Theo Smeets (Website & Info)

Prof. Theo Smeets

Trier University of Applied Sciences

Faculty of Design

Campus Gemstones and Jewellery

You are leaving the official website of Trier University of Applied Sciences