The aim of the project is to address current and future problems in the automotive industry and to develop innovative solutions in teaching and research. Contrary to the general trend in the vehicle industry, where the focus is on increasing driving comfort, driving experience and performance, vehicle concepts are being developed here that put the passenger car back in the spotlight as a flexible and efficient means of transportation. The main focus is on climate and environmentally compatible mobility.

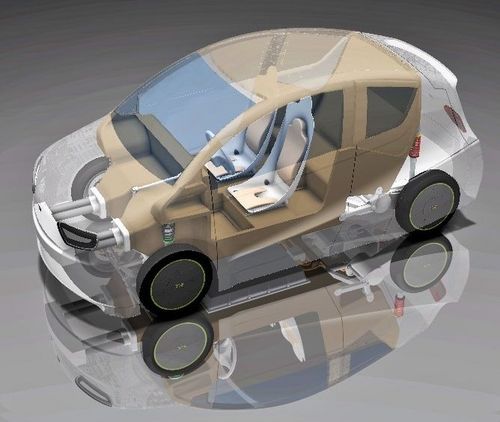

The proTRon EVOLUTION is a highly efficient local transport vehicle for 2+2 passengers. With a maximum speed limited to 100 km/h and a minimum range of 100 kilometers, the vehicle is designed for commuter traffic close to the city and shorter interurban routes. It can cover over 90% of all daily trips in the private sector. Two electric motors on the rear axle provide the drive.

The electrical energy is supplied by a battery, which can be supplemented by an optional "comfort module" to further increase the range, with a fuel cell or a second battery unit supplying energy. Thanks to consistent lightweight construction and an innovative safety concept, the vehicle, with a total weight of just 550kg (including battery), meets all the requirements for approval in accordance with class M1 (StVZO), including crash safety, and is being developed with a view to possible series production.

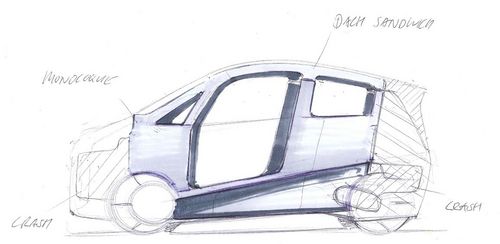

To ensure sufficiently high passive safety at the lowest possible vehicle weight, a fiber composite monocoque forms the safety cell for the four occupants. We solve the conflicting goals of weight and safety as well as deformation and occupant acceleration through targeted energy conversion in deformation elements in a small space. This specifically reduces the large acceleration forces generated by the high rigidity of the monocoque. The basic structure of the monocoque consists mainly of natural fiber composites and is only locally reinforced with unidirectional carbon fibers in a load-path-oriented manner. This concept is a genuine world first.

A major advantage of natural fibers lies in their overall energy efficiency, as the energy required from production to the component is considerably lower than for carbon fibers. Furthermore, the damping properties in favor of comfort and the splintering properties in favor of passive safety in the interior speak in favor of their use. Extensive basic tests are being carried out in this context.

You are leaving the official website of Trier University of Applied Sciences